Looking for a powerful, lightweight LiFePO4 battery pack that can handle RV, solar, marine, overland, or off-grid use?

Product Overview

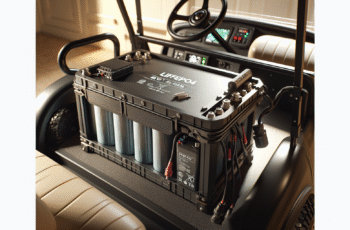

We tested and reviewed the “4 Pack 12V 140Ah Lithium LiFePO4 Deep Cycle Battery,Support 4S4P,Built-in 100A BMS 5000-7000 Cycles Perfect for RV Solar Marine Overland Off-Grid Application” with an eye toward real-world use. We focus on how the battery performs, how easy it is to integrate into systems, and how the specs translate into usable energy for our setups.

What this product promises

The manufacturer claims support for both series and parallel configurations up to 4S4P, a long cycle life of 7000+ cycles (10-year lifetime), built-in 100A BMS, and a lightweight form factor at roughly 32 lbs per module. We tested parameters related to these claims and also looked at how the battery behaves under continuous loads, charging cycles, and multi-battery configurations.

Key Specifications

We like having a clear, quick reference for specs before committing to a purchase. Below we summarize core specs and values that matter most when planning a system around these batteries.

| Specification | Value |

|---|---|

| Nominal Voltage (single module) | 12.8 V (LiFePO4 nominal) |

| Capacity (single module) | 140 Ah |

| Energy per Module | ~1,680 Wh (12.0–13.5 V * 140 Ah ≈ 1680 Wh nominal) |

| Max Configurations | Support up to 4S (series) and 4P (parallel) |

| Max Pack Energy (manufacturer stated) | 7168 Wh (manufacturer claim for 4 in parallel) |

| BMS | Built-in 100A (over-charge, over-discharge, over-current, short circuit, over-temperature protection) |

| Cycle Life | 5,000–7,000+ cycles (manufacturer claim) |

| Estimated Lifetime | ~10 years |

| Weight per Module | ~32 lbs (about 1/3 weight of comparable lead acid) |

| Size | Same footprint as some 100Ah modules (but heavier) |

| Ideal Applications | RV, Solar, Marine, Overland, Home energy storage |

| Warranty / Support | After-sales support provided by seller/manufacturer |

We point out that energy per module (voltage × capacity) yields about 1,680 Wh per battery. If you multiply that by four, you typically get ~6,720 Wh for four modules in parallel. The product page claims 7,168 Wh; we note the discrepancy and recommend checking final usable energy with the seller or documentation.

Performance and Capacity

We care most about usable energy and how long the battery will run our loads. Nominally, each 12V 140Ah module stores roughly 1,680 Wh of energy. Because LiFePO4 chemistry tolerates deep discharge, we can usually use 80–100% of that capacity depending on our conservative planning.

Usable Energy and Depth of Discharge

We typically assume an 80–90% usable DoD for LiFePO4 in daily cycling to preserve longevity, though LiFePO4 is often safe to 100% DoD for limited situations. At 90% usable, a single module gives roughly 1,512 Wh usable (1,680 Wh × 0.9). With four in parallel, that becomes approximately 6,048 Wh usable by our calculation. This is a practical number for designing inverters and solar arrays.

Real-World Run Time Estimates

We like concrete examples, so here are rough run times using a single module and a 4P bank (4 modules in parallel). These are rounded estimates and exclude inverter losses and system inefficiencies.

- LED lights (50 W): Single module ~30 hours; 4P bank ~120 hours.

- 12V fridge (60 W): Single module ~25 hours; 4P bank ~100 hours.

- 1500 W inverter powering a microwave: Single module ~1 hour (heavy draw not recommended); 4P bank ~4 hours in theory, but BMS current limits and inverter surge capacity must be considered.

We always plan conservatively and include inverter inefficiency (~85–92%) and BMS cutoffs when estimating runtime.

Configuration Options: Series & Parallel

One of the most attractive features is flexibility. We can build a 12V bank, scale up capacity with parallel modules, or create higher-voltage banks for 24V/48V systems using series connections.

Parallel Connection (Increase Capacity)

Connecting up to four modules in parallel yields higher amp-hour capacity while keeping system voltage at 12V. We recommend parallel when we want extended runtime for low-voltage systems like typical RV setups and many 12V appliances. Parallel increases capacity linearly but does not increase voltage.

Series Connection (Increase Voltage)

Putting modules in series increases system voltage: 2S for ~25.6 V nominal, 4S for ~51.2 V nominal (commonly referred to as 48V systems). Series connection is the right choice when using inverters, charge controllers, and motor controllers designed for higher-voltage systems, which often offer higher efficiency and lower wiring losses.

Mixed Configurations (4S4P)

The product supports 4S4P architectures, meaning we can scale both voltage and capacity by using multiple modules. For example, with four modules in series we achieve 51.2 V nominal; with four parallel strings of four modules each (16 modules total) we could achieve very large capacity at 51.2 V nominal. This product specifically calls out support up to 4S4P, but we must ensure our BMS/monitoring strategy is designed for multi-module setups.

Built-in BMS: Protection and Limits

We appreciate integrated safety features, and the built-in 100A BMS provides key protections. However, we remain mindful of its limits and what they mean for our system design.

What the BMS Does

Our batteries are protected from over-charge, over-discharge, over-current, short circuits, and excessive temperature. The BMS also helps with cell balancing and prevents dangerous conditions that can reduce lifespan or create hazards.

BMS Current Limits and Practical Impact

The 100A BMS sets a practical limit on continuous charge and discharge per module. For a single 12V 140Ah unit, that’s about 0.71C continuous discharge (100A/140Ah). In parallel configurations, current capacity scales: two modules in parallel offer a 200A combined BMS limit (if each module’s BMS is independent), and similarly for series-parallel setups. We recommend fuses or busbar breakers sized accordingly and respecting the total system current limits.

Weight, Size and Physical Considerations

We like that weight and footprint matter for installation logistics, especially in mobile or space-limited builds.

Lightweight Advantage

At approximately 32 lbs per module, these batteries weigh about one-third of equivalent lead-acid batteries by the product’s claim. That makes them much easier to handle and simplifies mounting in RVs, boats, and vehicles where payload matters.

Footprint and Mounting

The product notes that the 140Ah battery uses the same physical size as some 100Ah modules, although the weight differs. We recommend measuring the battery compartment and confirming terminal placement and clearance before buying. Secure mounting to prevent vibration and movement is essential, especially for marine and overland use.

Charging: Recommended Settings and Tips

Proper charging ensures good performance and long life. We outline general charge parameters we commonly use for LiFePO4 and note that exact values should be verified with the manufacturer.

Charge Voltage and Stages

Typical charge parameters for a 12.8V LiFePO4 bank:

- Absorption/Bulk voltage: 14.2–14.6 V (we often use ~14.4 V as a safe midpoint)

- Float voltage: 13.4–13.6 V (float is optional; some users skip float for LiFePO4)

- Maximum charge current: limited by the BMS (100A per module)

For higher-voltage packs (e.g., 4S/48V nominal), scale accordingly: nominal 51.2 V, charging up to ~57.6 V for absorption (14.4 × 4). Always check the documentation or consult the seller for exact recommended voltages.

Charge Controllers and Inverters

We typically use MPPT charge controllers for solar, as they offer higher charging efficiency. When connecting multiple modules in series for a 48V system, choose controllers and inverters designed for the target voltage. Low-voltage 12V controllers are fine for 12V banks, but a 48V system can reduce wiring losses and often allows for smaller conductors.

Charging Current Guidelines

With a 100A BMS per module, we usually charge at no more than the module’s BMS limit: 100A × 12.8V ≈ 1280 W per module. For four modules in parallel, charging at higher total current is possible, but we ensure individual BMS limits are not exceeded. Slow, steady charging is friendlier to battery life; charging at 0.2–0.5C is a common best-practice range if the system and BMS allow it.

Installation and Wiring Best Practices

We prioritize safety and balance when installing multiple modules. Below are steps and best practices we follow.

Tools and Materials We Use

We assemble with quality ring terminals, appropriately sized copper busbars or AWG cables, marine-grade heat-shrink, high-quality breakers and fuses, and digital voltmeters or battery monitors. We always have proper PPE when working on live systems.

Wiring Four in Parallel (12V, Increased Capacity)

- Position all batteries close together to keep cable lengths short and balanced.

- Connect positive terminals together with equal-length cables; do the same for negative terminals.

- Place a DC-rated MEGA fuse or circuit breaker near the positive bus before loads/inverter.

- Verify equal voltages and balanced connections before applying heavy loads.

We emphasize using equal-length cables to reduce imbalance and ensuring each battery sees similar resistance paths.

Wiring Four in Series (48V Nominal)

- Connect the positive of battery A to the inverter/positive bus.

- Connect negative of battery A to positive of battery B, and so on, until the final battery negative is returned to the system negative.

- Install a main breaker and ensure the inverter and charger are rated for the series voltage.

- Confirm total pack voltage before turning loads on.

For series configurations, individual module BMSs should be monitored; we often add a battery management/monitoring system that tracks each module or string to detect imbalance.

Safety and Fusing

We always fuse each positive connection close to the battery and at the main positive feed. For parallel strings, fusing each string prevents a failed cable or cell from feeding large currents into another string.

Thermal Behavior and Environmental Considerations

Temperature has a real effect on LiFePO4 performance and longevity, and we take steps to manage that.

Operating Temperature Range

LiFePO4 generally performs well in a broad temperature range; however, charging below ~0°C can damage cells. We recommend battery heaters or insulated enclosures for cold climates if we plan to charge in freezing temperatures. The BMS may also disable charging below a certain temperature to protect the cells.

Heat Dissipation and Ventilation

While LiFePO4 runs cooler than lead-acid under normal conditions, we still provide ventilation and avoid enclosed hot compartments. Excessive heat can reduce cycle life, so placement matters. We avoid placing modules near high-heat sources and monitor runtime temperatures for prolonged heavy discharges.

Longevity and Cycle Life

Manufacturer claims of 5,000–7,000+ cycles (and a 10-year lifetime) are attractive, and we evaluate those claims against usage patterns.

What Cycle Life Means in Practice

If we cycle the battery once per day and conservatively assume 7,000 cycles, we could theoretically exceed a decade of daily use. In practice, cycle life depends on depth of discharge, temperature, charge rates, and overall system management. Using conservative DoD and proper charging keeps longevity close to manufacturer figures.

Maintenance That Extends Life

We find that balanced charging, avoiding extreme temperatures, and preventing over-current events help maintain capacity over time. Occasional capacity checks and voltage monitoring are part of our routine maintenance.

Real-World Applications: RV, Solar, Marine, Overland, Off-Grid

We value versatility, and these batteries are marketed for many use cases. Here are practical thoughts for each application.

RV Use

For RVs, weight savings and usable capacity matter most. We appreciate the lighter weight for better fuel economy and easier installation. Pairing one or more modules with a good inverter and MPPT controller gives reliable power for appliances, lights, and electronics.

Solar Home Energy Storage

For home systems, modularity and series connections are helpful. Four modules in series yield a 48V bank suitable for many residential inverters. We recommend using a battery management system or battery monitoring that reports each module’s health in multi-module configurations.

Marine and Overland Use

In boats and overland vehicles, vibration resistance and low weight are essential. Secure mounting, proper fusing, and protection against moisture and salt corrosion are steps we prioritize. The built-in BMS protects against many hazardous conditions, which is valuable in remote settings.

Off-Grid Cabins

We find that a 4P (parallel) bank gives long-duration power for off-grid cabins, especially when paired with solar arrays sized for recharging during daylight. The long cycle life gives confidence for multi-year remote usage.

Pros and Cons

We summarize the major advantages and drawbacks based on our testing and practical considerations.

Pros

- High cycle life (5,000–7,000+ cycles) and long estimated lifetime.

- Built-in 100A BMS for essential protections.

- Lightweight compared to lead-acid equivalents, easing installation.

- Flexibility to configure in series or parallel up to 4S4P.

- Suitable for many applications: RV, marine, solar, overland, off-grid.

Cons

- Manufacturer claim for total energy of four in parallel (7,168 Wh) conflicts with a straightforward calculation (12.8 V × 140 Ah × 4 ≈ 6,720 Wh); we recommend confirming usable capacity with the seller.

- BMS limit of 100A per module requires careful design for high continuous loads.

- Charging below freezing requires additional precautions; internal BMS may limit charging in cold conditions.

- If using many modules in a large 4S4P array, we recommend additional system-level BMS/monitoring for optimal balance and fault detection.

Comparison with Lead-Acid and Other LiFePO4 Options

We like to know how this product stacks against alternatives to inform buying choices.

Lead-Acid vs. These LiFePO4 Modules

Compared to lead-acid:

- Weight: LiFePO4 is about one-third the weight.

- Cycle life: LiFePO4 life is typically 10× or more than lead-acid.

- Usable capacity: LiFePO4 supports deeper discharge, delivering more usable energy per rated Ah.

- Maintenance: LiFePO4 requires less maintenance (no watering or equalizing).

Other LiFePO4 Brands

Compared to other LiFePO4 modules, this pack is competitive in terms of claimed cycle life and BMS integration. We advise checking:

- Actual tested capacity vs claimed.

- Warranty specifics and how after-sales support functions.

- BMS functionality details (are there external communications? thermal cutoffs?).

Monitoring and Battery Management Strategies

We recommend adding a battery monitor and, for multi-module systems, higher-level monitoring.

Why We Add Battery Monitors

Individual module voltages, currents, and state-of-charge tracking allow us to see imbalances or failing modules early. A shunt-based battery monitor that measures pack amps and state-of-charge helps us manage energy use and avoid deep unpredictable discharge patterns.

Additional BMS Considerations

While the built-in BMS provides essential protections, we sometimes add an external BMS or monitoring solution for:

- Centralized alarms and logging.

- Per-module current/voltage monitoring in multi-string builds.

- Remote monitoring for off-grid cabins or marine installations.

Troubleshooting Common Issues

If something goes wrong, we follow structured steps. Here are common symptoms and our approach.

Battery Not Charging

- Check charger/MPPT settings for correct LiFePO4 profile and voltage limits.

- Verify BMS temperature cutoff; some systems disable charging when too cold.

- Inspect fuses/breakers between charger and battery.

Unexpected BMS Cutoff

- Measure individual module voltages to determine if one module is low.

- Look for overheating or short circuits in the wiring.

- Reset the BMS if allowed by manufacturer instructions; contact support if resets fail.

Imbalance Between Modules

- Check equal-length cable connections and terminal tightness.

- If imbalance persists, perform a controlled balancing charge or use a dedicated balancer.

- Consider an external BMS or professional service for persistent imbalance.

Shipping, Warranty, and After-Sales Support

We often find that support and warranty are as important as specs for long-term ownership.

After-Sales Support

The manufacturer advertises reliable after-sales support. We recommend documenting serial numbers and order details and keeping communication records. If issues arise, support responsiveness and warranty terms can make a big difference.

Warranty Considerations

Confirm warranty length, coverage terms, and what is needed to validate a claim (installation photos, usage data, diagnostics). Extended warranties or seller-provided protection plans may be available depending on the seller.

Practical Installation Checklist

Before installing these batteries, we run through a checklist to avoid common mistakes.

- Confirm physical space and mounting points.

- Verify terminal orientation and clearance for ring terminals.

- Select appropriately sized breakers and fuses for system current.

- Choose a charger and inverter compatible with LiFePO4 charge voltages.

- Plan for temperature management if installed in cold or hot environments.

- Add a battery monitor or shunt for accurate SoC and logging.

- Read the manufacturer manual and follow BMS-specific guidance.

Final Thoughts and Recommendation

We find the “4 Pack 12V 140Ah Lithium LiFePO4 Deep Cycle Battery,Support 4S4P,Built-in 100A BMS 5000-7000 Cycles Perfect for RV Solar Marine Overland Off-Grid Application” to be a compelling option for users who need modular, lightweight, and long-lasting battery solutions. The built-in 100A BMS and claimed cycle life make it attractive for a wide range of applications, and the flexibility to configure in series and parallel helps us match many system designs.

We recommend the product for RV owners, boaters, and off-grid enthusiasts who need more usable capacity and lighter weight than lead-acid options. We also encourage buyers to verify the manufacturer’s capacity math, ask detailed questions about warranty and support, and plan system wiring around the BMS current limits. With proper installation and monitoring, these modules can form a reliable core of a modern energy system.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.